All of Deanna’s sculptures are custom commissions. Over the past 30 years, she has developed an inclusive creative process that includes the client and the incorporates all the project requirements from the beginning. Leveraging her training as a graphic designer, she creates realistic and beautiful concept drawings for clients to select from. She then iterates the design and incorporates client feedback until the design is perfect. With many projects in commercial and health care spaces, Deanna smoothly accommodates LEED certification, OSHA regulations, building code, structural engineering, and architect and interior designer teams to deliver impeccable artwork on time.

Here is how Deanna manages a typical project:

First Point of Contact

Deanna and client discuss the project and brainstorm what sculptural directions will suit the space. Construction timing, structural requirements for the sculpture’s weight and accessibility, lighting and durability are common areas of focus.

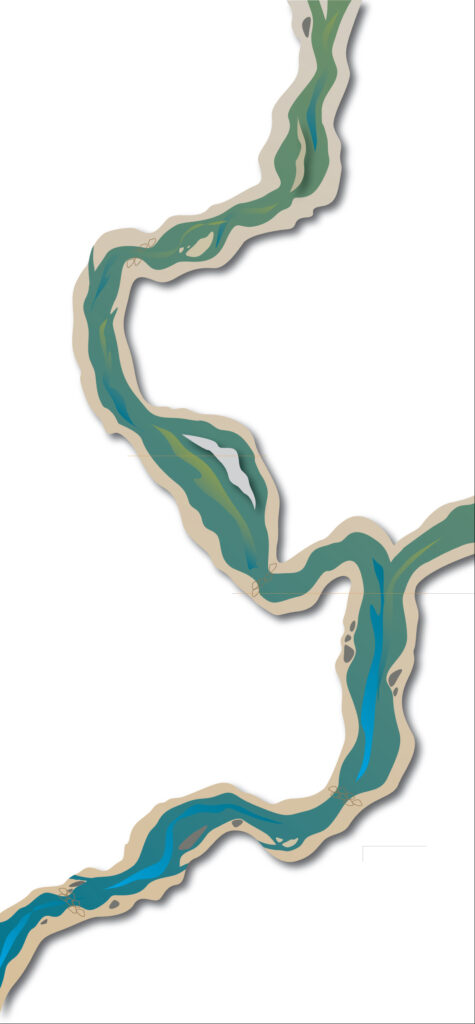

This project for Enermodal Engineering of Canada was created to honor the river restoration work the company had undergone while building their new headquarter building along the banks of the Grander River. Deanna walked the river bank and paddled the waterway to understand the geography and ecosystem, photographing details and consulting maps. The sculptural solution would fit a 3-story high atrium wall in the entry lobby of the building. The final design represented four seasons of change flowing down the wall as the glass river moved from frozen winter state to spring melt, blooming summer and fall color change.

Design Proposals

Deanna creates several design options based on the site visit, architectural plans and space renderings. The client and creative team evaluate the solutions and a final direction is chosen. At this stage budget and estimates need to align, construction site managers need to be included and timelines penciled in.

Final Design

Deanna works the design to incorporate client feedback and strengthen the design solution. She selects glass and material samples with the client to convey the look and feel in advance of investing in materials. She submits final drawings and any engineering details to the creative team for review.

Sketches to Templates

Deanna often creates full size templates from the approved final design drawings for the glass and metal components. This process ensures the sculpture is built precisely to measurements. Additionally, the template is often used during installation to speed the process of correct positioning before drilling holes.

Fusing Glass

Deanna hand cuts and composes each piece of glass and fuses it in her kiln. Many pieces require multiple fusings to add texture or 3-D form.

Metalsmithing

Deanna utilizes a variety of hand techniques and industrial manufacturing processes to cut, shape, bend, and finish the metal.

Putting it all Together

Deanna takes care to package the sculpture for safe transport. Crating and shipping multi-part sculptures requires a team who understands the strengths and weaknesses of glass combined with best shipping methods based on worldwide destinations.

Installation Day

Deanna and her crew meet on site. First they position the full scale template on the wall and then begin attaching the hanging hardware. Often scissor lifts are required.